Can Apprenticeships Fill the Skills Gap in Manufacturing?

Keith B. Belton

On June 15, 2017, President Donald J. Trump signed an executive order to expand apprenticeship programs across the United States in order to match workers to open jobs, “including 350,000 manufacturing jobs currently available.” At the signing ceremony, he announced, “We are empowering companies, unions, industry groups, [and] federal agencies to go out and create new apprenticeships for millions of our citizens.”

The executive order established a Task Force on Apprenticeship Expansion, led by the Department of Labor (DOL), with a mission to identify specific proposals that would promote apprenticeships. In October, DOL announced the members of the task force, which include representatives of major corporations, organized labor, and workforce training advocates. Their mission, however, is complicated by a lack of clarity about the underlying problem and a general lack of understanding of apprenticeship programs. Expanding apprenticeships represents not just a different way of educating, but a cultural change in the way society values credentials. Is a Master Electrician certification perceived to be as valuable as a Ph.D. degree?

The Skills Gap

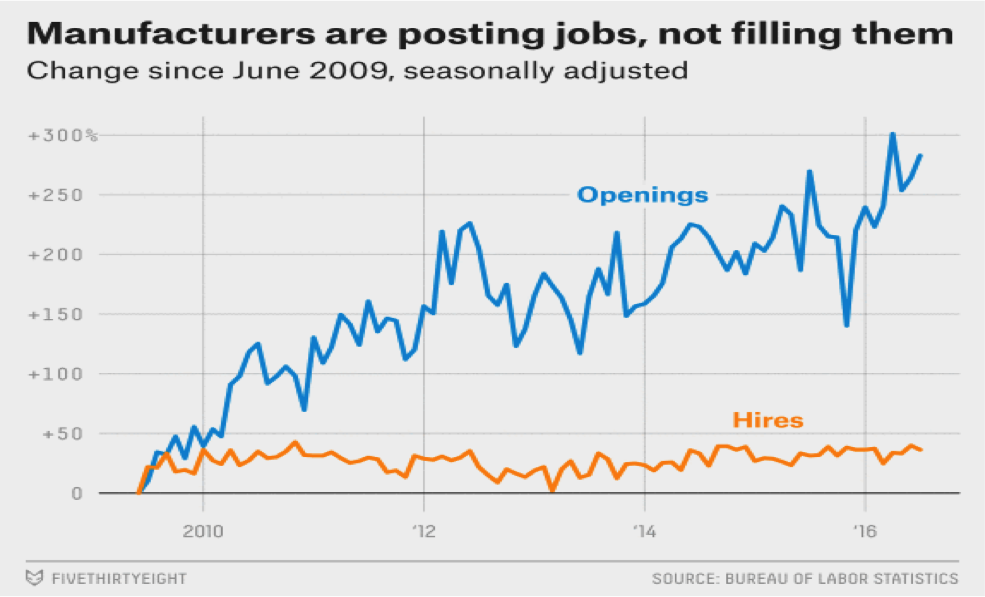

Since the Great Recession, manufacturers consistently point to a skills gap—they cannot find enough skilled workers to fill job openings. Since 2009, the number of job openings in the manufacturing sector has been growing while the much lower number of new hires has held steady. A 2015 nationwide survey conducted by Deloitte and the Manufacturers Institute concluded, “Over the next decade nearly 3 ½ million manufacturing jobs likely need to be filled. The skills gap is expected to result in 2 million of those jobs going unfilled.” This statistic is widely cited by policy makers. For example, on the day before the executive order was issued, White House Senior Advisor to the President, Ivanka Trump said, “Workforce development is critical, the skills gap is real…if we stay on the current trajectory, 2 million [manufacturing jobs] will remain unfilled…we are at a tipping point.” The problem could even worsen with the digitalization of the manufacturing sector, requiring skills that do not even exist today.

Other lines of evidence, however, do not reinforce the presence of a nationwide, persistent skills gap across manufacturing. For example, wages are not rising as they would if a skills gap exists. And longitudinal surveys of plant managers in manufacturing do not indicate labor shortages as a major factor for factories operating below capacity. In a 2016 nationwide survey using precise questions, researchers (Weaver and Osterman 2017) determined that three quarters of manufacturers do not show signs of hiring difficulties. Of those that do, the greatest hiring problems are found in establishments that are members of clusters or demand highly specialized skills.

The exact nature and magnitude of a skills gap are critically important to discern. For example, is the perceived gap due to fewer job applicants, a lack of qualified job applicants, and/or a reluctance by manufacturers to train new hires? If applicants lack needed skills, what exactly are the skills that are needed? Are these educational skills (i.e., obtained through the public education system), occupational skills (i.e., obtained through trade schools or by employers), or employability skills (e.g., having a strong work ethic, being a team player)? Any policy prescription ought to be informed by answers to such questions. Despite uncertainty over the nature and magnitude of the skills gap, policy makers have been spurred to action. One politically popular solution is to promote and expand apprenticeship programs.

Figure 1: The gap between job postings and new hires continues to grow in the U.S. manufacturing sector. Source: FiveThirtyEight from U.S. Bureau of Labor Statistics data.

Apprenticeships

An apprenticeship is a unique form of workforce training, combining on-the-job training under the supervision of seasoned professionals with classroom instruction over a defined period, usually leading to some sort of certification and a full-time job opportunity. Apprentices contribute to production while undertaking training. Apprenticeships can either be registered (through the U.S. Department of Labor) or non-registered.

Apprenticeships are not new and are utilized across the globe. In some countries (e.g., Austria, Germany, and Switzerland), apprenticeships represent the norm for developing skilled production workers in the manufacturing sector.

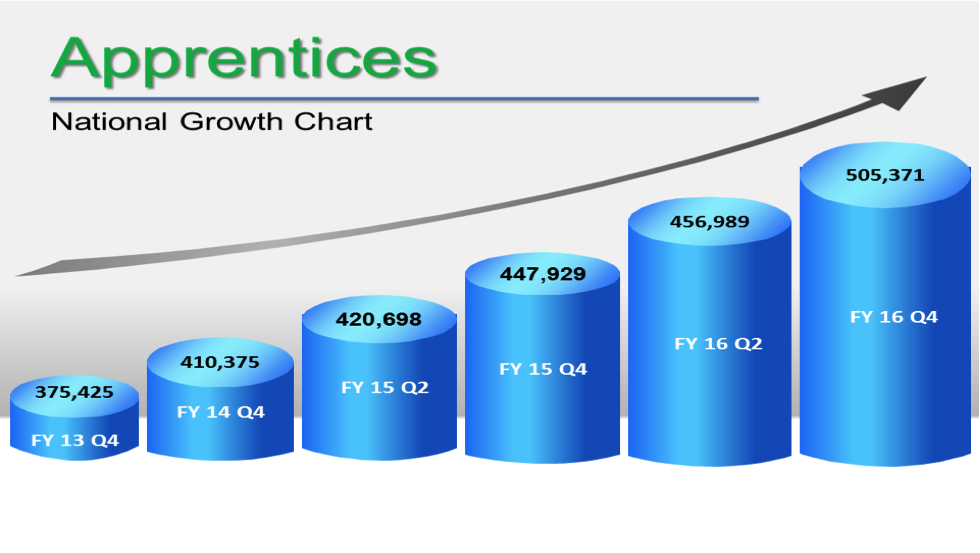

The U.S. government has long regulated apprenticeship programs. The 1937 Fitzgerald Act established a federal program within the Department of Labor to set standards, provide for the registration of apprenticeship programs by program sponsors, and monitor state agencies that often manage the program. Sponsors (individual employers or a group of employers sometimes in collaboration with unions) have considerable flexibility in designing and offering programs that meet DOL performance standards. According to DOL, in FY 2017 there were 22,487 registered programs (encompassing approximately 1,900 unique occupations serving a wide range of sectors of which manufacturing is just one), in which there were 191,000 new entrants, 539,000 active participants (89,000 in the military sector), and 51,000 completers. However, approximately 70 percent of registered apprenticeships are in the building and construction trades. Only about 7 percent are in manufacturing.

Registered apprenticeship programs are known to have positive employment and earnings outcomes for participants, according to a multi-agency review of job training programs. A 2007 survey of registered programs found that most sponsored programs have been around for a decade or longer, most sponsors would recommend federal registration to others, and poaching by other firms is not perceived to be a serious problem.

However, we know relatively little about apprenticeship programs that are not registered with the federal government. How do these non-registered programs compare in quality to registered programs? How many non-registered programs of similar or higher quality exist? Are these evenly distributed across manufacturing subsectors? Why do some sponsors choose not to register their programs? Answers to these questions would be very useful to policy makers.

Figure 2: The number of registered apprenticeship programs has been trending upward in the past few years. Source: U.S. Department of Labor.

What Can Policy Makers Do?

Policy makers can expand the number of apprenticeship programs by changing the incentives—either by lowering the cost of registered programs (e.g., by lowering the minimum requirements for registration, simplifying the registration process, providing incentives to the selling and organizing of apprenticeships, providing additional resources to assist sponsors) or by increasing the benefits (e.g., by providing a tax credit or subsidizing the off-job related instruction).

A thornier issue is how apprenticeship programs can best address the skills gap. To the extent the skills gap is a function of the low unemployment rate (labor economists say the U.S. economy is at or near full employment now), creating more employment opportunities through apprenticeship programs may not make much of a difference. And if the skills gap is concentrated in a few subsectors of manufacturing or within certain narrowly defined occupational categories, policy makers would best be advised to target their efforts in such a direction.

Firms may also choose to upgrade skills and jobs at the same time by adjusting their current job structure to the availability of skilled workers; workers may then be able to earn more as their productivity increases. As the manufacturing sector evolves through greater use of artificial intelligence and digitalization, many companies are planning to upskill their current workforce to the next level through apprenticeships.

The key to success, therefore, lies in better information and understanding about the underlying problem. Fortunately, such information can be gleaned though research, some of which is underway. The presidential task force would benefit from such information before it issues policy recommendations.

Peer reviewers: Sue G. Smith, Vice President, Schools of Advanced Manufacturing, Engineering, and Applied Science, Ivy Tech Community College, Indianapolis, IN and Robert I. Lerman, Institute Fellow, the Urban Institute, Washington, DC