Manufacturing USA: Evaluation and Recommendations

Download as a PDF

Tom Guevara

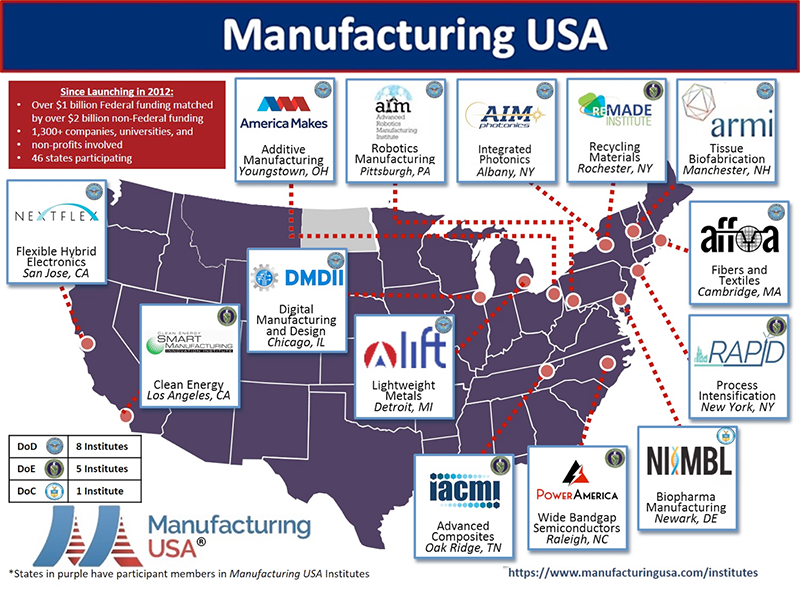

Ensuring the long-term competitiveness of the U.S. manufacturing sector is the purpose of Manufacturing USA, a federal program established in 2014 under the Reinventing American Manufacturing and Innovation (RAMI) Act. This federal program fosters collaboration across government, industry, and academia using a network of institutes, the aim of which is to bridge the so-called “valley of death” in precompetitive manufacturing technologies. Each of the current 14 institutes (Figure 1) focuses on a particular set of related technologies, such as advanced composites, photonics, and smart manufacturing. Institutes were established initially with funding from the Department of Defense, Department of Energy and Department of Commerce. Most also receive income from membership dues, which include private sector businesses and academic institutions. Some are some supplemented with state funding, such as Advanced Functional Fabrics of America in Massachusetts.

Five years after its creation, it is reasonable to ask: Is the program making progress? What lessons can be drawn? How can it be improved? As Congress considers whether to reauthorize the program (legislation has been introduced in both the House and Senate), answers to these questions are critical.

NASEM Workshops

The National Academies of Sciences, Engineering and Medicine (NASEM) has conducted two workshops on Manufacturing USA—one in 2017 and one in May 2019. The 2019 workshop focused on three topics: (1) the decline in U.S. (advanced) manufacturing capability and competitiveness, (2) the skills gap in advanced manufacturing, and (3) adoption of advanced manufacturing technology by small and medium sized manufacturers in the supply chain.

A publication summarizing the 2019 event, Revisiting the Manufacturing USA Institutes, contains several important insights for policy makers who are prioritizing the restoration of their region’s manufacturing competitiveness, and describes what leaders can do to build effective coalitions that support the advanced manufacturing needs of businesses in their regions.

Among the key findings:

- Innovation capability is linked to where manufacturing occurs.

- The Manufacturing USA program is effective in building networking and collaboration opportunities, and can serve as an effective model of collaboration between the private sector, academia and government to increase manufacturing competitiveness.

- Significant sustained investment in advanced manufacturing institutes is needed to provide the expertise required by businesses to be competitive.

- Measuring progress is necessary to ensure Manufacturing USA institutes are effectively serving industry and taxpayers.

The location of manufacturing matters. Separating R&D from supply chains and final production through, for example, offshoring, limits national competitiveness in several ways. Technology diffusion is seen as a key economic spillover from R&D conducted by the Manufacturing USA institutes with both large firms and small and medium size manufacturers (SMMs) benefitting. According to research by Willy Shih (Harvard Business School), the loss of domestic supply chains reduces a nation’s capacity to innovate. China is an example of a country that has increased its capabilities in advanced technologies by manufacturing production outsourced from the United States.

Separating R&D from where manufacturing occurs limits our knowledge of how to make things, according to Patrick Gallagher, University of Pittsburgh Chancellor and former Undersecretary for Standards and Technology at the U.S. Department of Commerce. Applied research centers such as the Manufacturing USA institutes have a primary purpose of bringing R&D closer to manufacturing supply chains to increase manufacturing “know-how.”

Unfortunately, business investment in R&D has declined in recent years compared to historic averages.[1] Erica Fuchs (Carnegie Mellon University) identified outsourcing (that has separated R&D from production) as a potential reason for companies not to invest in R&D in the United States. In her research, industries where this has been observed included optoelectronic semiconductors, automobile bodies, solar technologies, and certain battery technologies.

The institutes foster networking and collaboration. Several workshop participants identified important collaborative opportunities created by Manufacturing USA institutes. For SMMs Manufacturing USA institutes enabled greater access to potential partnerships with larger companies. These potential partnerships, such as ones created through public-private partnership of the Institute for Advanced Composite Manufacturing Innovation, are based on niche capabilities that may be possessed or needed by SMMs, and supported by the research capabilities offered by larger firms and participating universities, plus resources from the public sector which can address market failures in innovative activities.

In addition to bringing together industry firms of all sizes through the convening power of these public-private R&D centers, Manufacturing USA institutes have stimulated greater focus on other important industry/sector needs, such as workforce skill building, engineering solutions, and ensuring robust supply chains.

These collaborations bring the opportunity to accelerate the commercialization process for advanced technologies, which can take 10 years or more.

Sustained investment is necessary. The lifecycle of high-tech products and processes can last decades, and sustained support from manufacturing institutes for the R&D and workforce needs of businesses should match this lifecycle.

According to Ira Moskowitz of the Massachusetts Technology Collaborative, Manufacturing USA institutes have shown some positive impact on acceleration of technologies to commercialization, but the acceleration potential can be improved with state investment. Recognizing the impact that can be created with state partnership, Mr. Moskowitz noted that the State of Massachusetts has committed to investing $100 million in several Manufacturing USA institutes.

Many presenters opined, however, that Manufacturing USA institutes are too new to understand the full impact.

In addition to investments in the applied research capabilities of Manufacturing USA institutes, several presenters noted that these centers can and must be more engaged in workforce development. In addition to filling gaps in hiring qualified employees, especially for smaller firms, workforce training and certification programs also may create more innovation capacity into the advanced manufacturing sector. Student and worker engagement in project-based problem solving and engineering design challenges were two notable examples of a replicable approach to increasing advanced manufacturing workforce capacity.

Metrics of progress are needed. As with any investment of public funds, it is important for accountability to measure what successes or outcomes are expected. Several workshop participants said that common success metrics, such as increasing commercialization or technology transfer to the private sector, are important for focusing on the most important activities and desired outcomes from Manufacturing USA institutes.

Implications

Long cycle times against a backdrop of greater global competition and capability in commercializing high-tech products and processes may be creating a disincentive for firms to fund R&D at scale. Furthermore, advanced manufacturing often arises from collaboration among researchers from industry, government, and academia, which is time consuming and expensive. The remedy? Patient capital via public support.

R&D centers that combine public and private resources also serve as convening places for a broad set of expertise from business, academia and the nonprofit sectors. The resulting communication and collaboration can be instrumental in adoption and use of advanced manufacturing capabilities throughout the supply chain.

These centers can be an important resource for identifying and training the kind of workforce needed to operate sophisticated, high-tech machines and equipment, especially for SMMs that lack internal training resources, as well as helping to forecast future skills needed for competitive advanced manufacturing.

Insufficient investment in R&D and workforce skill building for advanced manufacturing is creating a U.S. vulnerability to competitive forces from overseas, particularly China. The lack of investment in applied R&D by SMMs—integral to robust supply chains—presents a particular threat to long term U.S. manufacturing competitiveness. For example, the inability to maintain a robust domestic supply chain for sensitive technologies, such as defense systems, increases security risks in industry and for our national defense.

Recommendations

Rebuilding long term U.S. competitiveness will require coordinated sustained efforts and resources from federal, state and local governments, in partnership with the private sector and academia.

Manufacturing USA institutes should be engaged in active outreach to SMMs to ensure that technical capability is diffused throughout the supply chain, which will increase manufacturing know-how, innovation and workforce training necessary to respond to competitive market forces.

R&D centers, such as the Manufacturing USA institutes, should be part of any regional, state or national manufacturing workforce training plans and demand forecasting efforts. They are in a strategic intersection between the leading edge research that precedes innovation and the hands-on knowledge needed to produce high tech products on the manufacturing line.

Tom Guevara is Director of the Indiana University (IU) Public Policy Institute.

[1] National Science Board, Science & Engineering Indicators 2018, National Science Foundation.

For further reading:

Bonvillian, William B. and Peter L. Singer. 2018. Advanced Manufacturing: The New American Innovation Policies. MIT Press: Boston.

Mahoney, Thomas and Sridhar Kota. 2018. Manufacturing Prosperity: A Bold Strategy for National Wealth and Security. MForesight: Ann Arbor.

National Academies of Sciences, Engineering, and Medicine. 2017. Securing Advanced Manufacturing in the United States: The Role of Manufacturing USA: Proceedings of a Workshop. Washington, DC. The National Academies Press. https://doi.org/10.17226/248275.

National Academies of Sciences, Engineering, and Medicine. 2019. Revisiting the Manufacturing USA Institutes: Proceedings of a Workshop. Washington, DC: The National Academies Press. https://doi.org/10.17226/25420.

Pisano, Gary P. and Shih, Willy C. 2012. Producing Prosperity, Harvard Business Review Press.

Peer reviewers: Sheila A. Martin, Vice President of Economic Development and Community Engagement, Association of Public and Land Grant Universities, and Tom Mahoney, Associate Director, MForesight.